- ABB ROBOTSTUDIO SETTING A TOOL HOW TO

- ABB ROBOTSTUDIO SETTING A TOOL INSTALL

- ABB ROBOTSTUDIO SETTING A TOOL PC

“Predicting the braking behavior of a robot with its payload will help system integrators and end users save time and costs, with up to 25 percent reduction in the footprint when it comes to designing and building a robot cell or setting up a safety zone. "Our new robot braking distance function for RobotStudio equips the user with information about a robot’s real-world movements with an unprecedented level of accuracy,” says Antti Matinlauri, Head of Product Management for ABB Robotics. The new RobotStudio function uses ABB s superior motion control technology to predict the robots movements with millimetric precision. Release date: Nov 10, 2021, Size: 1.9 GB. Enabling the robot’s braking distance to be accurately calculated, the function overcomes the need to add safety margins into cell designs, enabling space savings of up to 25. Allowing users to design, configure and commission everything from individual robots to complete robot systems in a virtual environment, it allows solutions to be tested and refined before they are implemented in real life.

ABB ROBOTSTUDIO SETTING A TOOL HOW TO

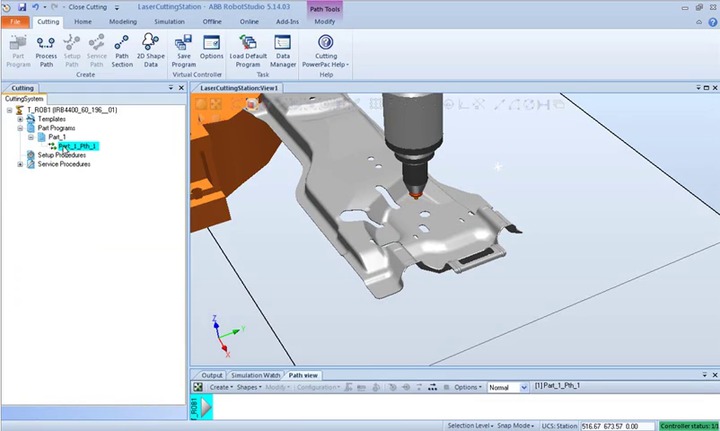

This tutorial shows the workflow for how to create a system with the 3DP RobotWare Add-In, setup a RobotStudio station with the same system, and how to generate a print program with the 3D Printing PowerPac. ABBs RobotStudio software continues to set the standard for robot simulation and offline programming. This is especially beneficial in collaborative applications where operators need to be confident that a robot has stopped before approaching it. ABB’s RobotStudio offline programming tool enables users to create, simulate and test a complete robot installation in a virtual 3D environment without having to visit or disturb their actual production line. This tutorial shows how to schedule multiple prints by setting up a Print Queue from the FlexPendant. The tool is built on the ABB Virtual Controller, an exact copy of the real.

ABB ROBOTSTUDIO SETTING A TOOL PC

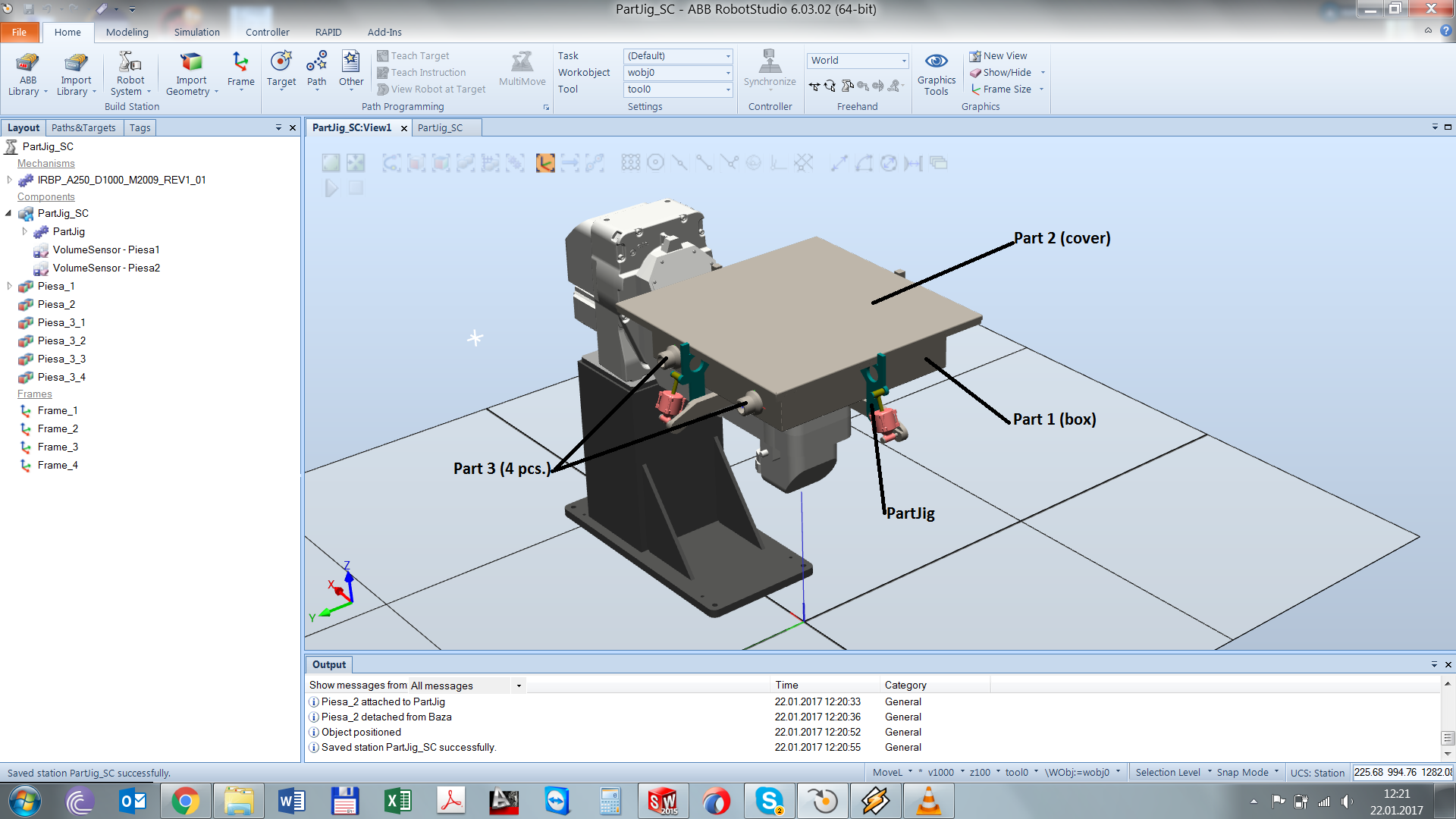

This allows the exact movement of the robot to be simulated in RobotStudio, enabling the user to determine the correct size of the safety zone required, and the ideal location of features including light curtains, safety fencing and controllers.įor applications using ABB's SafeMove software, the data on the robot's final position can be used to determine the size of the green, amber, and red zones where the robot will either continue working, slow down or come to a halt, depending on the location of the operator. ABB's simulation and offline programming software, RobotStudio, allows robot programming to be done on a PC in the office without shutting down production, this allows you to perform tasks such as training, programming, and optimization without disturbing the production. The new RobotStudio function uses ABB's superior motion control technology to predict the robot's movements with millimetric precision.

ABB ROBOTSTUDIO SETTING A TOOL INSTALL

RobotStudio contains the tool to install RobotWare onto the real. Several print screens from RobotStudio help to understand in a better way the process to operate RobotStudio and create robot programs off-line.Enabling the robot’s braking distance to be accurately calculated, the function overcomes the need to add safety margins into cell designs, enabling space savings of up to 25%. ABB AB Robotics Products SE-721 68 Vsters Sweden Table of Contents 1 Release. All the necessary procedures to create a given robot application are described, step-by-step. In this video I explain the basics of using ABBs RobotStudio to create a robot station to simulate real-time interaction with Machina.

It is divided in 4 modules in which each module is a different exercise. This guide contains the basic commands to start using ABB RobotStudio. Allowing users to design, configure, and commission everything from individual robots to complete robot systems in a virtual environment, it allows solutions to be tested and refined before they are implemented in real life. ABB RobotStudio® allows programming to be done on a computer without disturbing existing production. The first one is Signal Analyzer, being part of the RobotStudio software. RobotStudio® The toolbox for industrial robot users Computer-based programming is the best way to maximize return on investment for robotic systems, resulting in lower costs, faster time to market and superior end products. This guide/manual explains step-by-step the most common functionalities of RobotStudio.ĭepartment of Mechanical Engineering (POLO II), University of Coimbraġ. ABB’s RobotStudio software continues to set the standard for robot simulation and offline programming. Monitoring the performance of ABB robots is.

0 kommentar(er)

0 kommentar(er)